Innovate UK awards £500,000 to fund trials for AI robotics to sort plastics

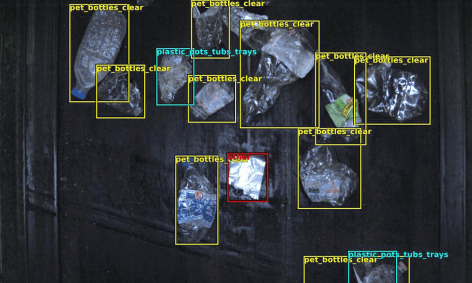

In a joint bid, London-based recycling company Paper Round with leading AI start-up Greyparrot and Middlesex University have been awarded £500,000 by Innovate UK, the UK’s innovation agency to develop an AI driven low-cost robotic solution to detect and recover plastics from mixed waste streams.

The technology will be retrofitted at Paper Round’s existing Materials Recovery Facility in Purfleet, Essex in summer 2021 for trials after lab tests.

The £500,000 grant will accelerate research on the integration of AI visual capability into third-party robotics.

Working with Greyparrot and Middlesex University, Paper Round will give feedback on captured images of plastics, as well as provide the waste data to train the AI vision system. They will also provide a testing site, to optimise the robotics and allow for greater accuracy of sorting.

The AI waste recognition software created by Greyparrot will be integrated into a third-party hardware system and will use deep learning technologies to solve complex visual problems to ensure robots can ‘see’ the waste with the same or better accuracy than humans. The software uses embedded prediction models that allow remote continuous monitoring and improvement.

Just under 60% of plastic bottles and 33% of pots tubs and trays are recycled in the UK and current automated processing solutions are unable to fully sort the wide-ranging variety of plastic types effectively at low cost.

Rapidly developing AI identification technology coupled with low-cost robotics offers the opportunity to help boost the recycling figure.

The project will serve innovators in the industry who seek intelligent software to power waste sorting machines.

Bill Swan, Managing Director of Paper Round said: ‘We are excited to be part of these trials. We see many different types of plastics on our sorting facility, and we welcome the opportunity to be able to more efficiently identify and sort these for recycling.’

Mikela Druckman, Co-founder & CEO of Greyparrot: “We are thrilled to be working with Paper Round on this innovative project. This grant also opens up collaborative opportunities to embed our waste recognition software with machinery providers to ensure products at the end of life are captured for recycling efficiently.”

Mehmet Karamanoglu, Middlesex University: “We welcome this fantastic opportunity to collaborate with our partners in tackling such an important issue. Being able to use our robotics and AI research expertise that will lead to tangible and practical outcomes is great to see. We are looking forward to helping make a significant contribution in tackling the challenges with rapid plastics identification and recycling.”

Vision Techniques launches thermo detection and facial recognition system

As the current COVID-19 pandemic sweeps the globe and dramatically alters the way we all go about our daily lives, governments and businesses are turning to advanced innovative technologies to limit the risk of contagion.

As the current COVID-19 pandemic sweeps the globe and dramatically alters the way we all go about our daily lives, governments and businesses are turning to advanced innovative technologies to limit the risk of contagion.

UK Government guidelines state that if employees develop a new, continuous cough or have a temperature of 37.8 degrees Celsius or above, they must self-isolate and get tested.

To support businesses with the challenges they face in keeping their staff, customers and visitors safe, safety technology company, Vision Techniques, better known for their vehicle safety solutions, have launched VT IPATH.

VT IPATH is a high temperature alert system that identifies body temperatures often associated with viruses and infections such as the existing COVID-19 virus, seasonal flu, common colds and many other transmittable disorders.

VT IPATH detects and measures temperature and provides an accurate reading of a person’s body temperatures in real time, records and notifies of an abnormal temperature, and enables you to make quick and informed decisions to protect your employees’ and visitors’ health.

In addition to VT IPATH’s temperature monitoring ability, the system also provides clear identification, using facial recognition, enabling you to accurately match recorded data to individuals.

This functionality can also be used as an entry control system – alerting you to unauthorised personnel.

The system works by alerting both the individuals directly and the system administrator if an abnormal body temperature is detected and by recording the captured data in the system’s back end for historic reporting.

WRA welcomes outcome of BEIS consultation on waste wood biomass

The Wood Recyclers’ Association (WRA) has welcomed clarification from the Government that non-domestic WID compliant RHI boilers are allowed to continue to use post-consumer waste wood as biomass fuel.

The Wood Recyclers’ Association (WRA) has welcomed clarification from the Government that non-domestic WID compliant RHI boilers are allowed to continue to use post-consumer waste wood as biomass fuel.

The announcement follows a consultation run by the Department for Business, Energy and Industrial Strategy (BEIS) on the closure of the non-domestic Renewable Heat Incentive Scheme to new applicants, which is due to come into force on March 31st this year.

Richard Coulson, incoming Chair of the WRA, said the announcement made yesterday, was common sense.

“Energy companies have invested millions of pounds in abatement technology to ensure compliance and safe handling of wood fuel in order to produce renewable energy,” said Richard. “It made no sense to propose that non-domestic Chapter IV compliant boilers could not continue to use fuel derived from post-consumer waste wood.

“Indeed this is the best outcome for the environment as many forms of post-consumer waste wood can be difficult to recycle and the recycling capacity to handle all of this waste type is also not available,” he added.

The consultation, which received 132 responses from industry and the wider public, has concluded that it will be mandatory for RHI biomass plants “to comply with a fuel quality standard and to carry out annual maintenance checks on their biomass boilers in order to increase efficiency and improve air quality emissions.”

In addition it states: “We will not restrict the burning of waste-wood in biomass boilers since existing processes already provide a good enforcement regime for waste-wood”.

Richard added: “Pre-consumer waste wood such as manufacturing and joinery offcuts is much easier to recycle and therefore it’s correct that it should be re-used or recycled first.”

Workshop construction starts on EPIC Media Group site

Work has started on the construction of a purpose-built specialist workshop for EPIC Media Group.

Work has started on the construction of a purpose-built specialist workshop for EPIC Media Group.

The large purpose-built unit is capable of accommodating two large commercial/recycling vehicles with plenty of space to work on them.

The new facility will have a controlled environment that provides the optimum conditions for fitting the graphics, electric vehicle charging points and an external hardstanding work area. In addition, there will be parking capacity for a fleet of vehicles within a gated property with CCTV and on-site security.

The construction of the building shell took two weeks. It is now being fitted out with the necessary services and heating control systems.

The external ground works will be finished with the facility due to be fully operational by the end of February.

Kevin Murton, Managing Director of EPIC Media Group said: “It’s been a bit of a challenge getting this project to site given the current COVID situation, but we are delighted to finally see it taking form now. Our team of fitters are really looking forward to using the new facility.”

The workshop brings a number of benefits, including increased capacity due to reducing travel times, a reduced carbon footprint as well as offering a space for third party companies to come and fit their products to the vehicles.

“Space is often at a premium at vehicle manufacturing plants, so this facility will reduce the burden on the manufacturers while the trucks are being fitted out with the additional accessories.

PiP IoT partners with Yotta to enhance smart asset management solutions

PiP IoT, the New Zealand-based manufacturer of ultra-rugged IoT sensing devices for Smart City and infrastructure monitoring applications, has signed a collaborative agreement with Yotta, a leading UK-based connected asset management software and services provider.

PiP IoT, the New Zealand-based manufacturer of ultra-rugged IoT sensing devices for Smart City and infrastructure monitoring applications, has signed a collaborative agreement with Yotta, a leading UK-based connected asset management software and services provider.

The partnership will enable both companies to offer PiP’s sensing devices and Yotta’s asset management software together as a fully integrated end-to-end solution for smart asset management.

The two companies first worked together in 2018 on a pilot project with Auckland System Management (ASM) to help improve motorway safety in Auckland by detecting when vehicles struck motorway crash barriers. Through working together on the project both PiP and Yotta have recognised strong synergies, offering significant customer benefits, when their capabilities are combined as a comprehensive, pre-integrated and proven system.

Data driven decision-making has the ability to deliver better outcomes for organisations in terms of sustainability, efficiency, operational costs and customer experience.

Through the partnership the two companies will refer each other into public sector and infrastructure monitoring opportunities such as highways, streetlights, waste, trees, playgrounds and drainage, and will help each other expand into their respective territories.

“Yotta is a great fit for us because our sensors are engineered for monitoring exactly the kinds of assets that Yotta’s software platform is designed to manage. The data we can generate from our sensors can be leveraged really well through their platform and help deliver much more effective and efficient services for our customers,” says Nigel Sharplin, CTO, PiP IoT.

“A seamless integration between our respective capabilities ultimately provides the market with the data insights and toolset to deliver much better outcomes.”

JCB Finance marks £50 million Covid-19 support milestone

JCB Finance marked a milestone in its support of the UK construction industry during the coronavirus pandemic after delivering more than £50 million of loans.

JCB Finance marked a milestone in its support of the UK construction industry during the coronavirus pandemic after delivering more than £50 million of loans.

The vital cash has been distributed to the industry through the Coronavirus Business Interruption Loan Scheme (CBILS) – designed to support the continued provision of finance to UK smaller businesses (SMEs) during the COVID-19 outbreak.

As an accredited lender, JCB Finance has been assisting new and existing customers impacted by COVID-19, who need to invest in JCB equipment or other qualifying plant and vehicles.

Through JCB Finance customers have been able to access the scheme, used to back a fixed rate hire purchase facility with a six month payment pause, then 48 monthly instalments, The Government will make a Business Interruption Payment to cover the first 12 months of interest payments and any lender-levied charges.

Among those who have successfully used the CBILS-backed facility is Monks Contractors, which has used it to invest in a new JCB JS20MH wheeled material handler and 30 new BMI ejector and walking floor trailers. Monks Contractors Managing Director Chris Monk said: “The pandemic and lockdown made everyone feel uneasy. Some form of disruption was inevitable, but we must look forward.

“It is essential we continue to invest and maintain our fleet to deliver the best possible service to our customers and the CBILS-backed Hire Purchase with JCB Finance has helped us to do this.

“I have used JCB Finance for years and have a great relationship with them; they offer a good combination of personal service and easy, uncomplicated online services that help save me time.”

The Chancellor of the Exchequer has announced a further extension to the CBILS scheme to 31st March 2020, giving more time for businesses impacted by COVID to apply. Successful applicants have 6 months from receiving the loan offer to draw down the facility, so this news is a welcome relief to those wishing to secure access to funds through to the autumn.

Craemer UK expands their UK Environmental Products Sales team

Craemer UK has announced the appointment of Graham Deuchars into their UK Environmental Products Sales team.

Craemer UK has announced the appointment of Graham Deuchars into their UK Environmental Products Sales team.

Based in Perth, Graham (pictured) will be responsible for driving business growth in Scotland and Northern Ireland, whilst building upon Craemer’s established reputation as a leading UK based supplier of high quality, long lasting wheeled bins and recycling containers into the public and private waste sectors.

Commenting on his new role, Graham said; “I’m delighted to be joining the team at Craemer. It will be a pleasure to work for a company who are market leaders, known for quality and have ongoing investment.”

Graham joins Craemer having enjoyed a successful sales career spanning over 30 years working for industry leading companies such as HC Slingsby, Arthur Shaw Manufacturing, Jewson and HCS Group.

Steve Poppitt, UK Managing Director said; “We are delighted to welcome Graham to our fantastic UK sales team at such an exciting time for Craemer following the recent expansion of our UK production operation and the introduction of a range of brand new products”.

Based in the Midlands and supplier to over 70% of UK councils and major municipal bodies, recent investment has seen Craemer UK as part of the Germany-based Craemer Group expand to a purpose built, second production facility running alongside their UK headquarters.

This state-of-the-art facility, and the addition of a full range of 4 wheeled bins along with a 340 litre bin and household food waste caddies completes their range of waste and recycling containers and establishes Craemer as the only UK based manufacturer with the ability to produce their entire range in-house.